Dynamics 365 Supply Chain Management

Build an adaptable, resilient supply chain that automatically reacts to challenges using real-time visibility, agile planning, and advanced insights.

Planning, forecasting, and inventory management

Plan with confidence and agility; Predict demand using AI and make inventory decisions with priority-based supply planning in near-real time, eliminating stockouts and overstocking.

Perform continuous planning in near-real time; Complete material requirements and resource planning in minutes so planners can react to demand changes in near-real time, leading to faster replenishment cycles and shorter delivery lead times.

Improve demand forecasting; Enrich historical demand data with AI predictions powered by Microsoft Azure Machine Learning to improve forecasting for future supply levels.

Eliminate stockout situations; Strategically position inventory with stock buffers to minimize the risk for stockouts using demand-driven material requirements planning (DDMRP) to automatically generate supply orders.

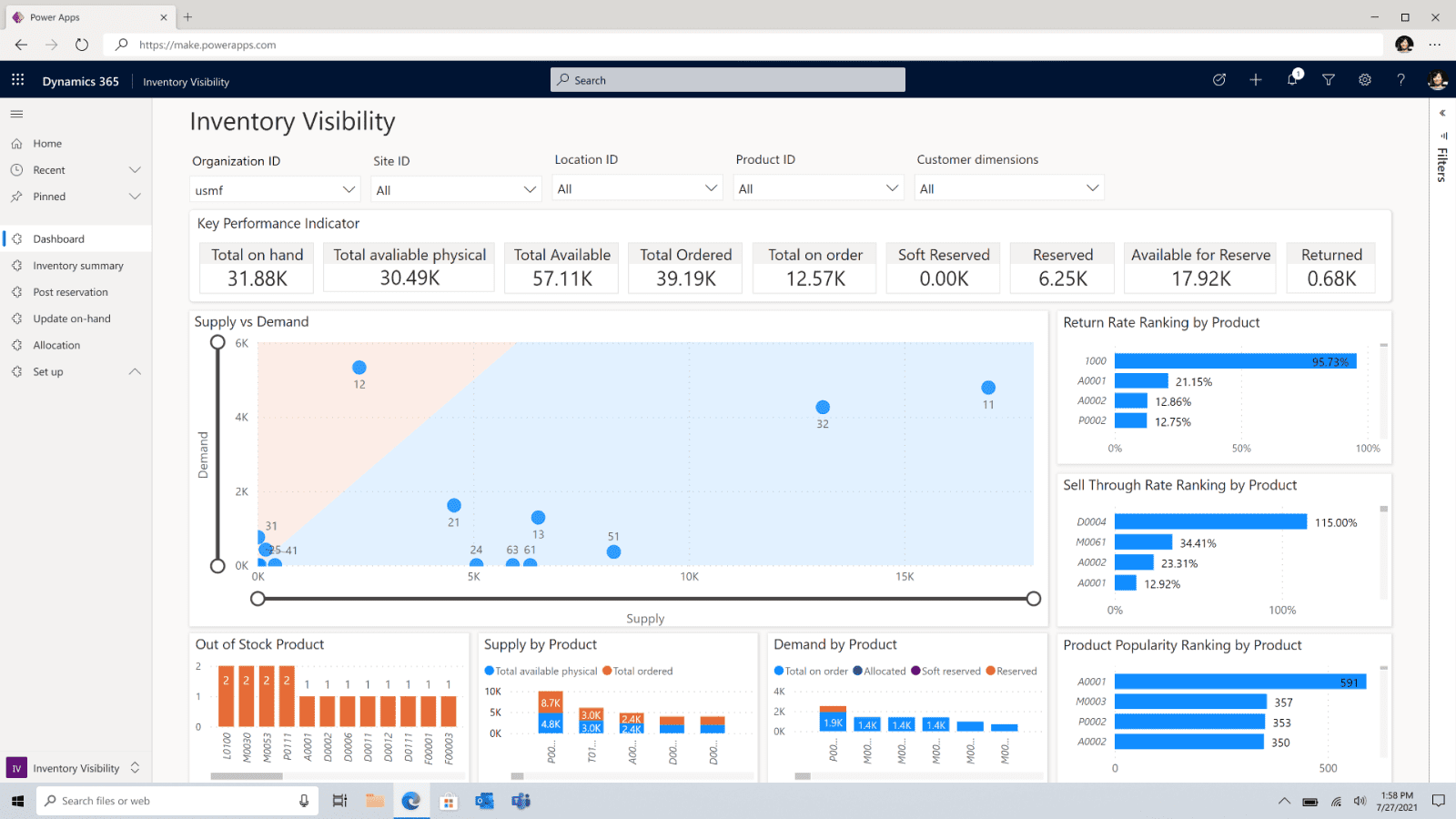

Optimize inventory placement; Ensure that the right products are in the right place at the right time with inventory allocation (preview). Get a single view of inventory across channels and allocate inventory for specific needs or customers.

Collaborate in real time; Effectively communicate across sales, marketing, and operations using Microsoft Teams to streamline sales and operations planning.

Procurement and sourcing

Procure with insights and automation; Streamline procurement processes and improve cost management using vendor collaboration and advanced analytics to mitigate critical parts shortages.

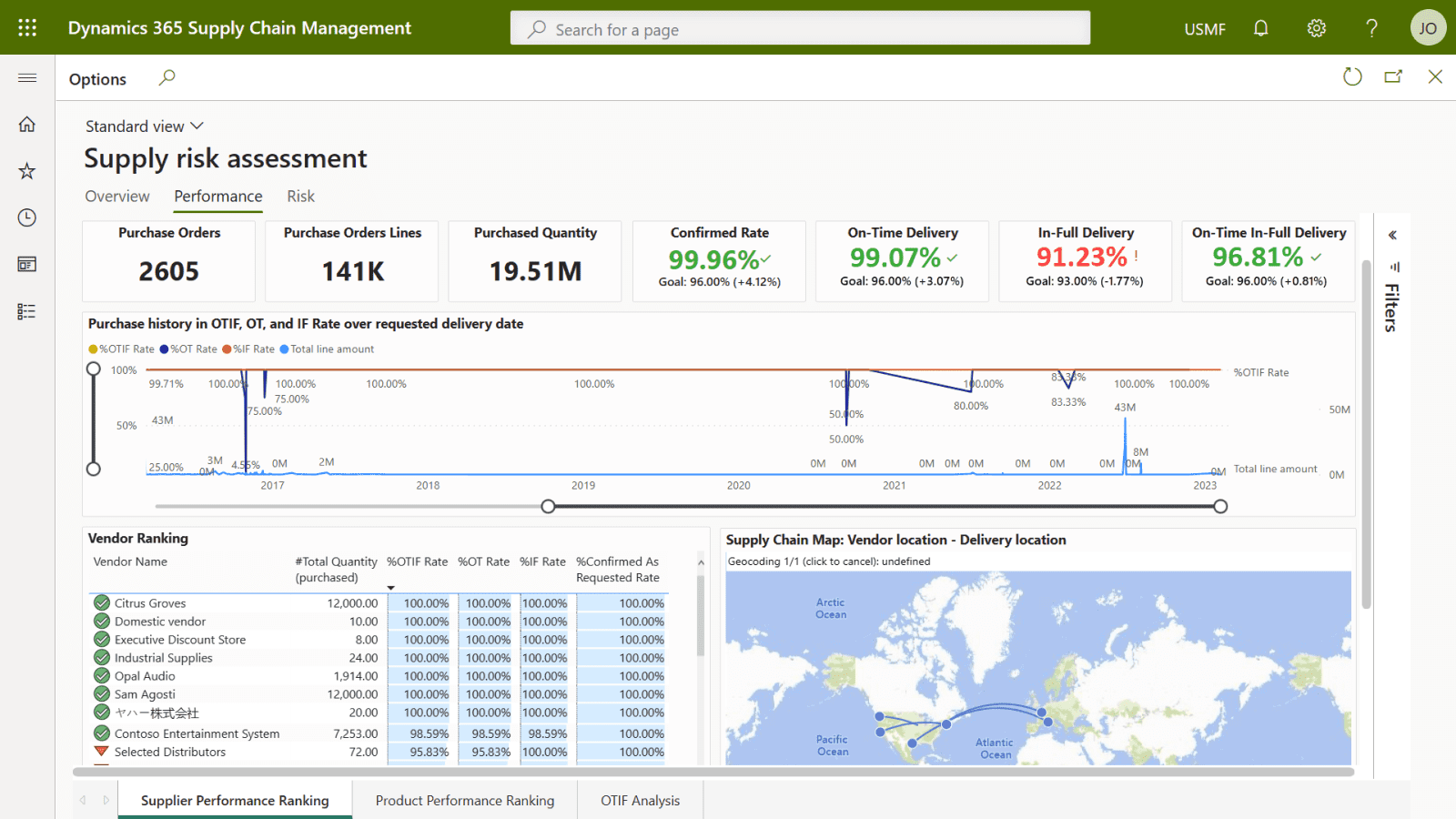

Assess supply risk; Uncover risks to planned purchases with data about past supplier performance and product metrics such as on-time, in-full delivery rates in a comprehensive workspace.

Improve cost management; Realize maximum cost savings by automatically applying negotiated pricing based on business-defined purchase policies.

Streamline vendor management and collaboration; Use a single, secure application to quickly onboard vendors and collaborate across procurement processes such as purchase order management, request for quotation bidding, and invoicing.

Maximize sourcing selections; Optimize your sourcing experience with punch outs to external vendor catalogs and explore more options to expedite order placement.

Make smart purchasing decisions; Effectively track vendor performance, lead times, and quality with embedded purchasing insights using built-in Microsoft Power BI templates.

Manufacturing and shop floor management

Manufacture with innovation and intelligence; Build agile manufacturing processes using the Internet of Things (IoT) and mixed reality while working with your existing manufacturing execution systems (MES).

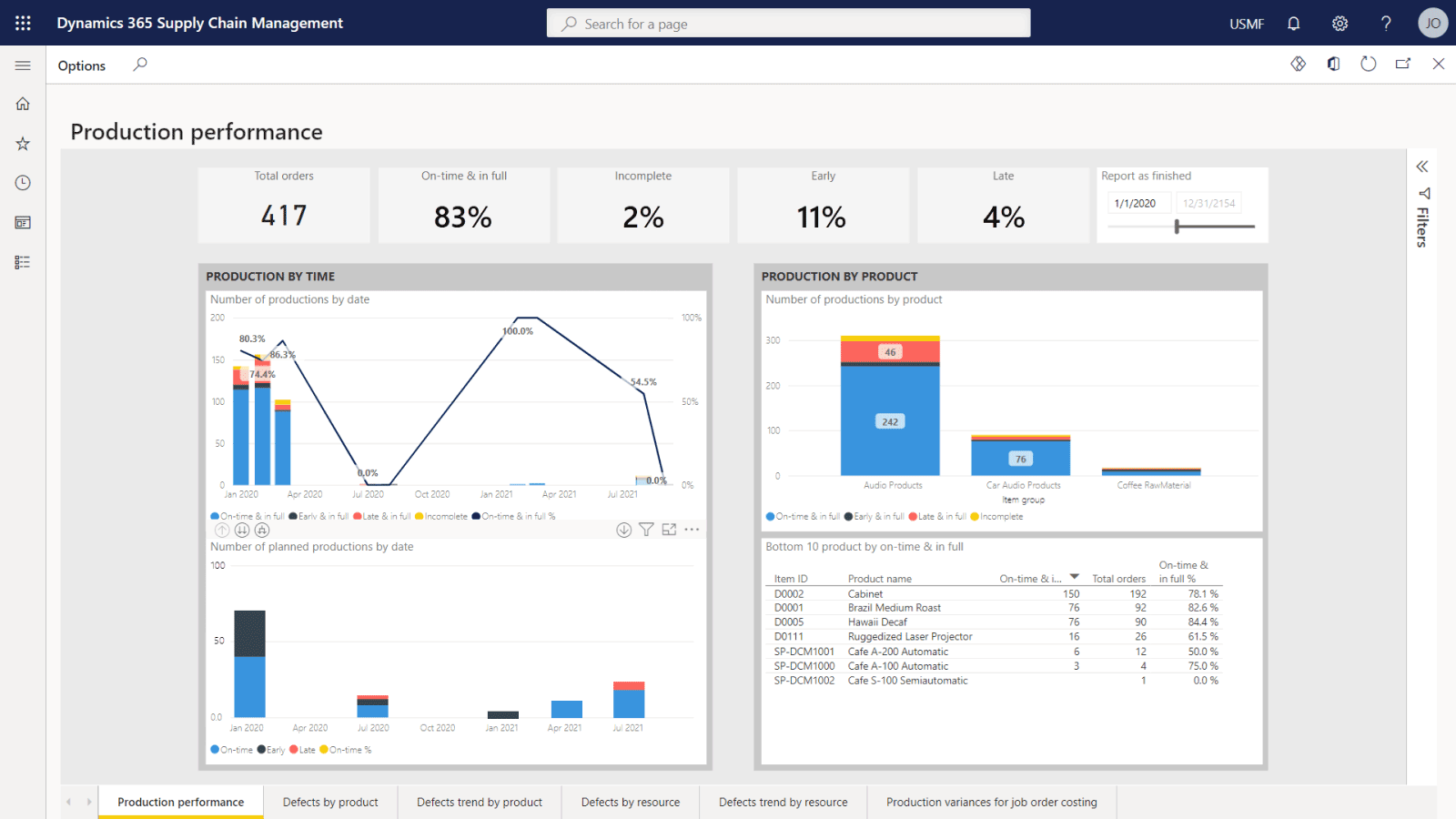

Create a connected factory; Proactively manage the shop floor using a real-time view of production and stock to improve quality, increase throughput, and reduce downtime with a modern production-floor execution user interface (UI).

Accelerate time to market; Implement sustainable and adaptable manufacturing processes using IoT and mixed reality to accelerate time to market for new products.

Enhance visibility of the production floor; Incorporate data from external manufacturing execution systems (MES) to eliminate data silos, improve quality, and optimize production processes with MES integration.

Transform your workforce; Improve safety, increase efficiency, and reduce errors by using the interactive holographic experience in Dynamics 365 Guides, available in the context of the current production job.

Simplify production accounting; Track costs accurately by using the Global Inventory Accounting Add-in to record manufacturing expenses in multiple currencies and cost-calculation methods.

Order management and pricing

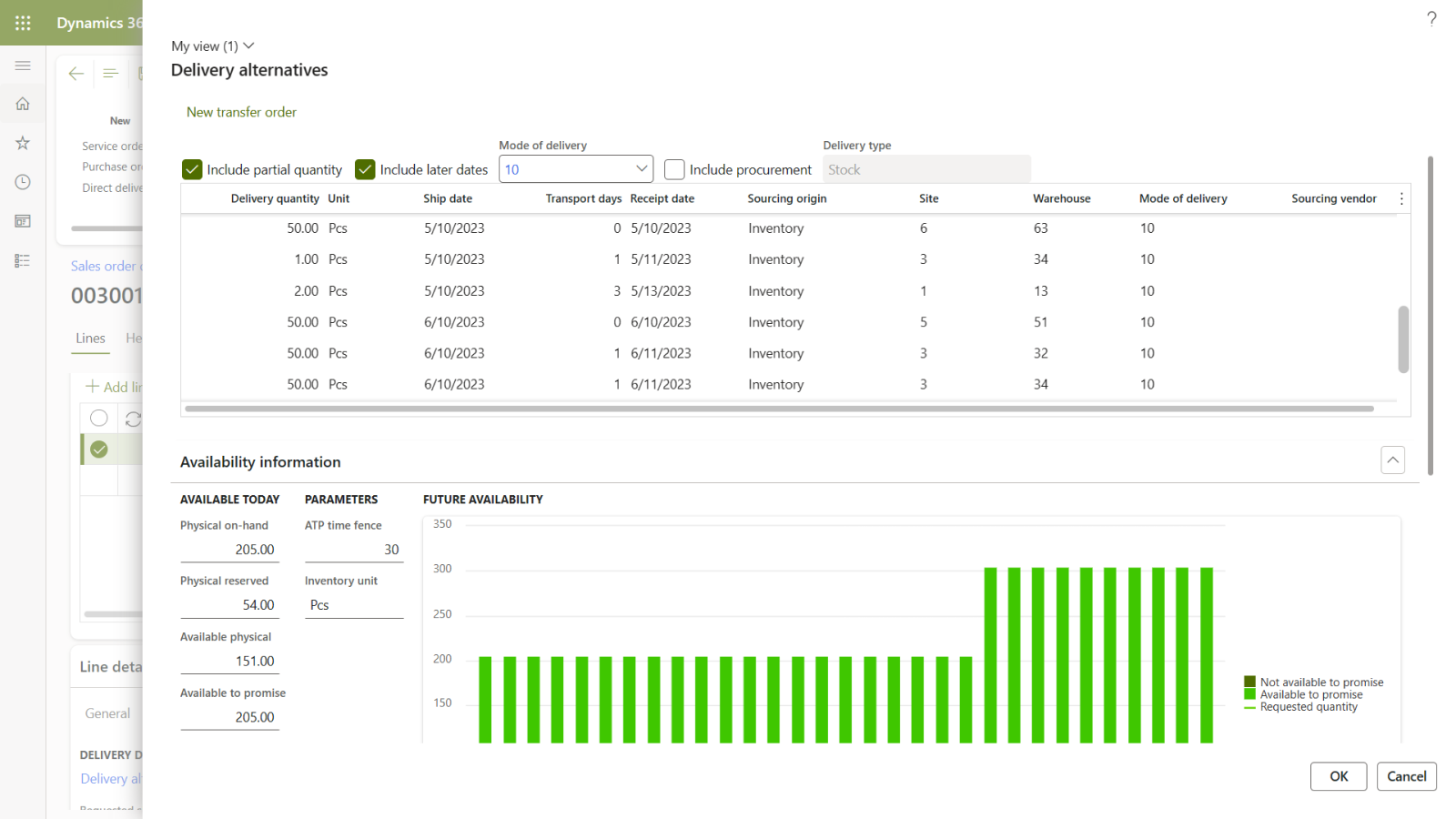

Optimize fulfillment for on-time deliveries; Leverage delivery alternative information such as on-hand inventory and future availability data to determine the fulfillment location for on-time and sustainable deliveries.

Deliver on customer promises; Provide accurate inventory information to customers at order entry and make reservations using real-time inventory and available-to-promise (ATP) data.

Maintain customer loyalty; Offer consistency in pricing with flexible rebate calculations, target transactions, and trade allowance–management capabilities.

Centralize pricing management; Make real-time pricing calculations across multiple channels and simulate pricing scenarios based on customer, product, and channel attributes (preview).

Streamline sales with a centralized workspace; Efficiently manage sales orders with a centralized workspace and gain real-time visibility into delayed orders.

Warehouse management and fulfillment

Deliver with consistency and expediency; Expedite delivery times by optimizing inventory, automating warehousing operations, and increasing throughput.

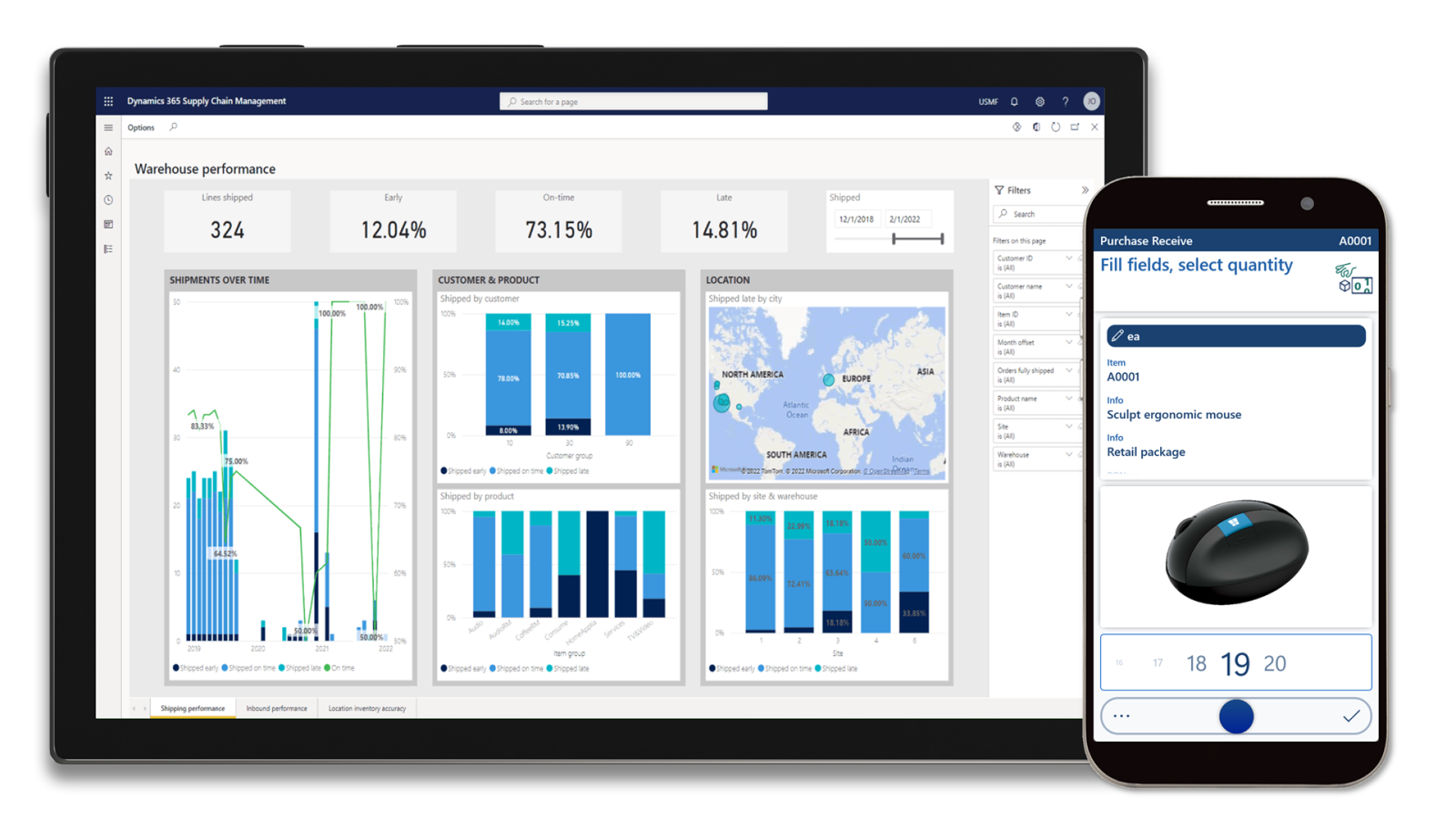

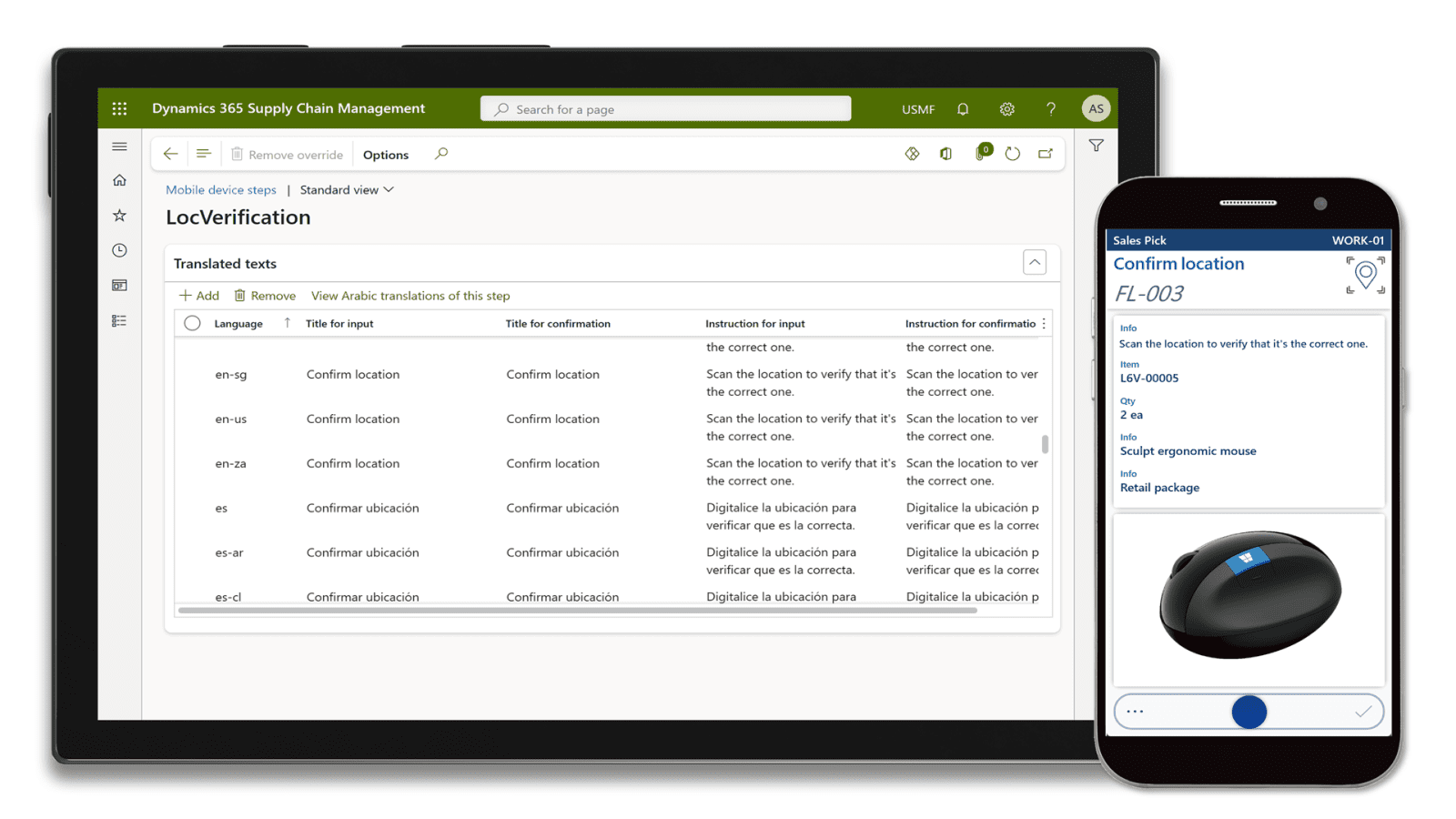

Increase throughput; Help ensure accurate and efficient warehousing operations using our intuitive and customizable mobile app, available on Android, iOS, and Windows devices.

Get up and running quickly; Establish new warehouses quickly with step-by-step, guided implementation wizards and the ability to copy configurations across warehouses.

Pick and pack with ease; Maximize fulfillment efficiency with guided, paperless picking, and pack and sort shipments from anywhere using a browser-based experience or mobile app.

Integrate with robotic MES; Mitigate labor shortages by augmenting warehouse staff with robotic automation for material handling, with built-in connectors to multiple providers.

Unify warehousing data; Gain insights into operations by consolidating data, including real-time inventory visibility, carrier data, and material-handling event information, to discover efficiencies.

Asset management and maintenance

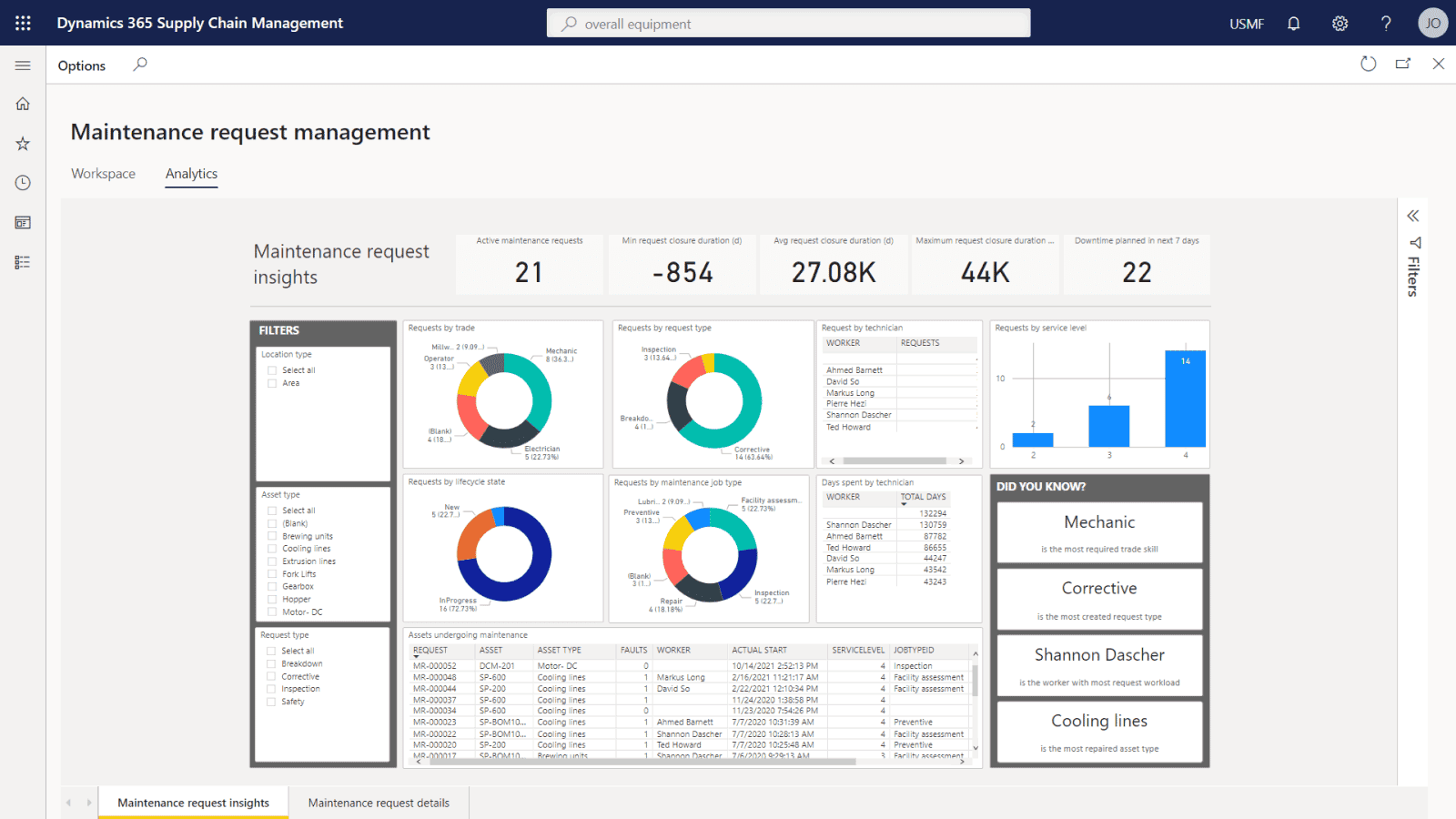

Operate with precision and foresight; Perform proactive or predictive equipment maintenance to reduce downtime and improve equipment effectiveness.

Reduce costly machine downtime; Proactively manage business-critical equipment by performing all types of maintenance—predictive, corrective, condition-based, and preventative—throughout the asset lifecycle.

Improve overall equipment effectiveness (OEE); Enable peak equipment performance using sensor data intelligence, and use IoT-powered data to drive proactive maintenance and improve OEE.

Request and perform maintenance on the go; View, schedule, and execute work orders for assets with an intuitive mobile app for asset management.

Synchronize maintenance and production scheduling; Optimize resource capacity utilization and avoid conflicts in maintenance work and production activities for geographically dispersed assets with advanced scheduling capabilities.